THE INTERVIEW

Sunjin Beauty Science - Microplastic Substitutes

Kim Sang-wook, Director of Research Institute, Sunjin Beauty Science

Microplastic particles have long been applied to various formulation of the cosmetics industry. This is because it improves the use of products and has various features such as sebum absorption and exfoliation. Although synthetic polymer particles such as PMMAPolyrnetyl metacrylate, polyurethane polyurethane, and nylon have been widely used, regulations on the manufacture and sale of fine plastic particles have been expanded in the cosmetics industry as environmental problems of U.S. Ceplastics have emerged worldwide. This is because it has emerged as a serious environmental problem as research has been continuously reported that not only natural decomposition requires a long time, but also requires artificial removal, which leads to the inflow of sewage into the sea and serious effects on the food chain of animals. Due to these issues, many industrial groups, including cosmetics, were in urgent need of replacing micro-polastics.

In response, Sunjin beauty science, a Korean cosmetics material company, developed a microplastic replacement using natural-originated silica from the origin of Neral 15 years ago. Silica, a natural origin ingredient, is used as a substitute material for microplastics but its dependence on foreign countries was high due to the nature of the functional particle market. In addition, due to physical properties of silica, PMMA could not be used as a complete replacement. Sunjin Beauty Science Research Team successfully developed pro-organic particle and reproduced various uses that only synthetic polymer particles had with its own natural coating technology.

Therefore, results of sunjin Beauty Science, which is based on domestic technology, has great significance both at home and abroad. It is expected that the developed micro-polastic replacement natural silica material will be applicable not only to make-up but also to various product groups such as skincare and sun care.

We met with Kim Sang-wook, director of the Sunjin Beauty Science Institute, and heard more specifically about the research. Kim, who joined Sunjin Beauty Science as his first job in 2006, majored in chemical processes and experienced various departments such as production, research, quality and sales. He is currently the general manager of research and sales headquarters.

What is the background of developing a microplastic replacement material.

This study began when we developed a wax bead to replace the microplastic issue, which was first applied to the wash-off product family. At that time, attempts to make wax beaded were made by many companies, including China and Europe, but there was a difference from the technology we developed. Most companies abroad used tap water to drip and harden water to make wax beads, which was very expensive because they produced only a small amount. On the other hand, we made PMMA and silica particles and were able to mass-produce them because they are emulsion types. As the market situation changed, microplastic issue expanded over various product types. We predicted the growth potential of the alternative market, and conducted a full-fledged study.

How did you end up using silica?

Sunjin Beauty Science is a material company that possesses original technologies based on surfactants and it has been 15 to 20 years since it localized Silica. We assumed that natural materials could replace microplastics if we use silica-based technology to produce material that has same physical properties with PMMA. To change the material properties of silica, we used natural coating technology developed by our company and elastic wax to conduct research.

How did you develop natural micro-particles that had different properties?

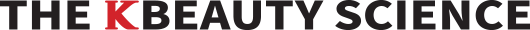

In order to understand the natural micro-particle we developed, we need to know the micro-polastic particle. There are four types of functions that are considered representative of these. First of all, the PMMA particle, which is nonporous, has a function that enhances the texture of cosmetics. And if you make a hole in a full particle, it's called porous PMMA, which minimizes stickiness by sucking in oil. These two types of PMMA have firm property. On the other hand, there are soft fine plastic particles, and nylon and urethane are the examples. In order to replace the properties of these microplastic particles, silica should be made with each of the properties described earlier, which basically have porous properties. PMMA is also a hydrophobic oil component, while silica is hydrophilic, so this should be made hydrophobic. Considering these parts, we used our surface coating technology and wax.

Please introduce the substitute developed by Sunjin Beauty Science.

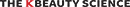

First, as shown in Figure 2, the NP of SUNSIL-l30NP stands for non-porous and is a substitute for non-porous PMMA. Basically, melting the porous silica slightly at high temperatures will block the hole and replace the non-porous PMMA.

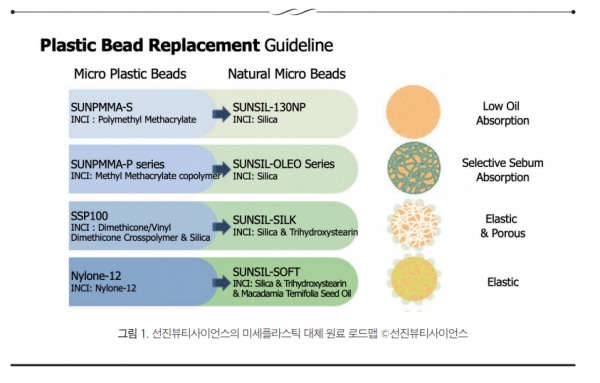

The second is a substitute for porous PMMA (Figure 3). Porous PMMA has the advantage of absorbing sebum well. Silica also has excellent absorbency. Silica is commonly used as a seaweed preservative. But there's an important difference between the two. While porous PMMA optionally absorbs oil first, silica randomly absorbs moisture and oil. When applied to cosmetics, silica had limitation as a complete substitute because it only wants to absorb oil while leaving moisture. Therefore, our research team made a strong chemical bond and coated inner and outer surface of silica with high-quality fatty acids, cetyl alcohol, which is arranged with 16 carbons. As a result, the optional ability to absorb oil has been revived, so it could be presented as an alternative solution for porous PMMA. The two solutions described earlier are to explain that hard micropolastic particles can be replaced.

Figure 3. SUNIL-OLEO Series, a porous PMMA alternative.

How did you develop a soft plastic particle substitute like nylon and silicon?

Silicon powder is a microplastic that absorbs sebum but is used a lot for a soft texture. It's often prescribed for a stick that's hardened with wax and made into a single oil form, and because the product comes directly to the skin, a softer texture is preferred. In the process, our research team used a wax called Trihydroxystyrene. This wax is more elastic and has softer properties than normal wax. Coating the silica and observing it with the permeable electron microscope TEM confirmed that the top surface has an embossed coating of tissue, as shown in figure 4. As a result, since silica and triiodroxisdearin are natural materials, it is a solution to replace silicon particles.

Nylon powder substitutes, which are commonly used in pressed products such as eye shadow press powder, were also developed as shown in Figure 5. Silicon particles should be non-absorbable if they have absorbent properties. So we pre-hopped natural-based water-oil inside silica and emboiled it with trihydroxydearin to confirm that the texture is similar to nylon particles.

Figure 5. Nylon particle replacement SUNIL-SOFT.

After first launch in April, how has the market responded?

Currently, most companies want products without fine plastic particles due to microplastic issues. Due to Covid-19, we are promoting it overseas through webinar. Considering that the samples made for each item ran out in a month, we could say it is quite successful.

I see that there's also finished product brand called "IRECIPE".

The reason why we made our own brand is that there are some parts that cause problems if we don't produce ourselves. Due to the different scale of experiments between laboratories (labs) and factories (pilots), the research team introduces the prescription solution that they have created directly to the customers. Based on this, we plan to move forward to a company that can provide more professional consulting with positions that play a middle role between OEM and raw materials.

What are your future plans?

We are currently conducting research on mineral Hexorite materials. There are many restrictions on the use of Hectorite because only one company owns the mine. We are currently working on a study to produce the material out of sourcing through different ways. I expect to hear good news soon.