Eui-Jung, Lee et al.

Su:m, Natural Fermentation Research Team, LG Life Science

ABSTRACT

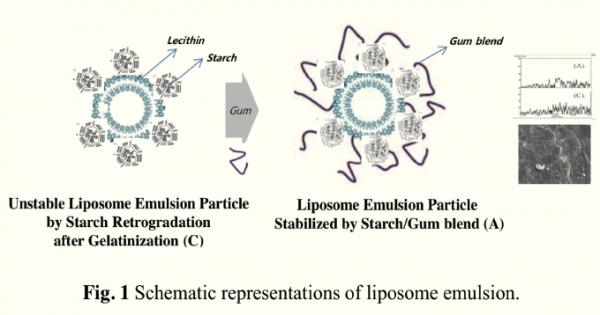

The objective of this work was to make emulsion with starch for natural cosmetics. For the cosmetic product with the high portions of natural grade ingredients, we could not use chemical stabilizers. Thereby, we investigated the effects of the amphiphilic starch and its stabilization for liposome emulsion. In this study, we conducted a starch crystallinity study to find the effect of gelatinization and retrogradation of amphiphilic starch with various types of gums using XRD, DSC and Cryo-FE-SEM techniques. To the best of our knowledge, there has been no report on the stabilization of liposome emulsion for cosmetics with native starch.

KEYWORD

starch crystallinity, gelatinization, gum, liposome, emulsion stability.

This study was jointly conducted by Eui Jung Lee, Hye-lim Hwang, Min woo Jeong, and Joo-young Oh of LG Life Science Cosmetic Research Institute and Professor Sung Kwon Hong of the Department of Polymer Science and Engineering, Chungnam National University. It is listed in Polymer(Korea) Vol. 42, No. 2, pp. 223-229 (2018).

What is Liposome Emulsion?

Liposome Emulsion refers to an emulsion formulation made from a raw material capable of forming a liposome such as lecithin, and is generally referred to as an emulsion composed of particles having a distinct lipid bilayer even under an optical microscope.

Background of Research

It is effective to use natural organic ingredients that are friendly to our body in order to develop " Safe cosmetics" that are free from various risks inherent in chemical raw materials. However, making emulsion formulations using only natural organic ingredients is a very difficult technology. This is especially true because unlike conventional cosmetics, artificial chemical stabilizers cannot be used in the stabilization of these safe cosmetics. As such, it is necessary to find a raw material that could maintain a stable emulsion formulation without chemical processing. It was also necessary to find a raw material which can have various functions in a single type of preparation in order to overcome the limitations associated with natural raw materials.

For how long have you studied natural cosmetics?

I have been working at LG Household & Health Care as a technical researcher for 17 years. I have been conducting this research before I transferred from my previous "Eco-Beauty" Research Team to my current Su:m & Natural Fermentation Research Team. The Eco-Beauty Team may not contribute significantly in terms of sales, but it is very valuable because of its emphasis on the "Authenticity" of its products. The team is continuously conducting research on the future with the goal of providing the safest cosmetics to customers. I first started conducting research on natural cosmetics in 2007. At the time, we started to develop products that meet the standards of the European market leading the field of natural organic cosmetics. Oil products using natural organic ingredients were relatively easy to develop, but it was not easy to develop emulsions and formulations. This is because the oil formulation is composed of a single system, but the emulsion is made of a multi-component system, which requires special technology to stabilize various components in the emulsion formulations. In particular, it has been very difficult to stabilize a formulation with a limited variety of natural raw materials. As such, we have tried to slowly approach a purely natural product rather than aiming for a complete natural product from the beginning. In the early stages of development, we started to develop organic materials with a goal of achieving 60% of organic ingredients. By gradually raising the content, we could produce emulsions made of organic ingredients in 100% by 2013. Although it was not enough to publicize, we are proud to have acquired the world's best technology in this field.

Why did you select starch?

After investigating natural raw materials that can be stabilized in the emulsion formulations, they became interested in starchy substances which can be used both to thicken the emulsion and improve the texture, while also having a stable odor. Starch is a non-toxic raw material that has undergone extensive research in the field of food. This is especially true in the context of cassava roots with tapioca starch, which are used as thickeners in the food sector, are a good material with low cost and high viscosity. In the field of cosmetics, it has been widely used for oil absorption and for its lubricant function with powder. In this study, liposome emulsion stabilization formulations were made by mixing guar gum and Arabic gum with tapioca starch. These results are the first research results on the stabilization of natural cosmetics.

About what is your research?

The study focused on the ability to make various formulations by controlling crystallinity through the amphipathic nature of starch. The effect of amphoteric starch was investigated by focusing on the morphological aspects of the polymer. We conducted a literature review on the utility of starch as an emulsifying stabilizer in liposome emulsion formulations when used with lecithin and the role of starch as a stabilizer in gelatinization in various formulations. We also conducted various experiments to analyze the morphological, thermal, and structural characteristics of the different gums, as well as the effects that mixing these gums can have, in order to prevent aging (retro-gradation, and β-degradation).

What is the focus of this experiment?

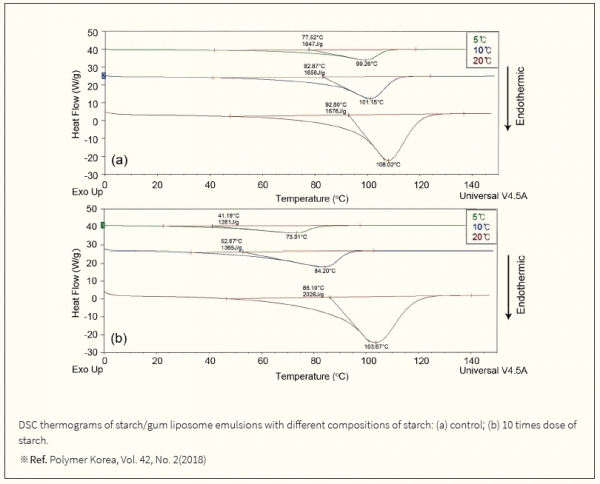

In order to investigate the factors influencing the aging of amphipathic starch and to investigate the characteristics of starch crystallization when mixed with various kinds of gums, various techniques such as XRDXray Diffraction, DSCDifferential Scanning Calorimetry, and Cryo-FESEMCryo Field Emission Scanning Electron Microscope were used. In the analysis, the stability of the DSC formulation will be evaluated by measuring the degradation temperature according to the contents of starch and gum constituting the emulsion. Experimental results showed that the decomposition temperature of the emulsion decreased with increasing starch content, while the difference in decomposition temperature between experimental samples increased with the content of gum. These results indicate that the content of gum affects the crystallinity of starch crystals of starch gum/emulsion. That is, as the amount of starch increases, the phase transition enthalpy decreases. These results are supported by the consistency of results when the rate of change in temperature is increased from 5°C to 20°C, therefore suggesting that this is not the process that is caused solely by the decomposition of starch itself. It was also confirmed that when the amount of starch added in the emulsion (wt%) was increased by 10 times or more, the transition temperature transition temperature decreased to a significant level. This means that the starch content also affects the transition temperature and increases the flexibility of the emulsion. Taken together, these results show that the stability of the emulsion can be controlled by adjusting the content of starch and gum.

What are the achievements and expectations of this study?

This study is a preliminary study that is essential for development of a safe, skin-friendly natural cosmetic emulsion formulation. The results support that liposome emulsion stabilization formulations can be made with just natural starch that is not chemically processed. The value of this result lies in its ability to solve the formulation stability issue, which was one of the biggest obstacles to the use of natural raw materials. We hope to utilize the emulsion stabilization technology of amphipathic starches started in this research to activate the development of functional organic cosmetics products using more natural ingredients.

It must have been difficult to write a paper.

It was not easy to write this article while working on product development as part of the company's product research team. It took a comparatively long time of 4 years to complete the papers with the development of the formulation and the production of the experimental data. However, since this study could become an essential foundation to the development of the first product of its kind, I had a great desire to publish the results as a thesis. I think I was motivated by this aspiration and faith to devote myself to this research without giving up and writing this paper.

Any words of wisdom for future researchers?

Before working at LG, I studied for a Bachelor's and Master's degree in the biochemistry field. While working as a formulation researcher after graduation at LG, I had a good opportunity to study polymer engineering in my doctoral program. As I studied polymer engineering, I could quench my thirst for knowledge regarding the development of differentiated formulations. As such, I recommend that younger researchers working in the formulation team study polymer science as well as chemical knowledge. Also, try not to limit the research to product development, but also try writing a formal paper on your results. Not only could I increase my sense of intellectual accomplishment by writing my thesis, but I could also build my own techniques for technology development. Other researchers working on formulations also hope to be able to increase their value as technical experts by publishing more papers.

REFERENCES

1. Robyt JF, Essentials of Carbohydrate Chemistry, Springer, New York, 1987.

2. Kim S, Peterson SC, Polym. Compos., 33, 904 (2012)

3. Temsiripong T, Pongsawatmanit R, Ikeda S, Nishinari K, Food Hydrocolloids, 19, 1054 (2005)

4. Alamri MS, Mohamed AA, Hussain S, Carbohydr. Polym., 89, 199 (2012)

5. Boudries N, Belhaneche N, Nadjemi B, Deroanne C, Mathlouthi M, Roger B, Sindic M, Carbohydr. Polym., 78, 475 (2009)

6. Mohamed A, Peterson SC, Grant LA, Rayas-Duarte P, J Cereal Sci., 43, 293 (2006)

7. Chantaro P, Pongsawatmanit R, Nishinari K, Carbohydr. Polym., 97, 512 (2013)

8. Fua Z, Wang L, Li D, Zhoua Y, dhikari BA, Food Hydrocolloids, 31, 183 (2013)

9. Chaisawang M, Suphantharika M, Carbohydr. Polym., 61, 288 (2005)

10. Chaisawang M, Suphantharika M, Food Hydrocolloids, 20, 641 (2006)

11. Chantaro P, Pongsawatmanit R, J. Food Eng., 98(1), 44 (2010)

12. Shaikh T, Kumar SS, Int. J. Pharm. Pharm. Sci., 3, 38 (2011)

13. Masuelli MA, Am. J. Food Sci. Technol., 1, 60 (2013)

14. Tischer CA, Gorin PAJ, Iacomini M, Carbohydr. Polym., 47, 151 (2002)

15. Pinto GL, Martinez M, Sanabria L, Food Hydrocolloids, 15, 461 (2001)

16. Mhinzi GS, Mghweno LAR, J. Food Chem., 107, 1407 (2007)

17. Yebeyen D, Lemenih M, Feleke S, Food Hydrocolloids, 23, 175 (2009)

18. Wang S, Li C, Copeland L, Niu Q, Wang S, Compr. Rev. Food Sci. Food Saf., 14, 568 (2015)

19. Palyvoda S, Urchak V, Golikova T, Fomenko V, Food Environ. Saf., 12, 300 (2013)

20. Puri R, Gill BS, Khetra Y, Int. J. Food Sci., http://dx.doi.org/10.1155/2014/564564.

21. Shinoda K, Araki M, Sadaghiani A, Khan A, Lindman B, J. Phys. Chem., 95, 989 (1991)

22. von Corswant C, Thoren PEG, Langmuir, 15(11), 3710 (1999)

23. Bibi S, Kaur R, Henriksen-Lacey M, McNeil SE, Wilkhua J, Lattmann E, Christensen D, Mohammed AR, PerrieInt Y, Int. J. Pharm., 417, 138 (2011)

24. Tan G, Xu P, John VT, He J, McPherson GL, Agarwal V, Bose A, Langmuir, 24(19), 10621(2008)